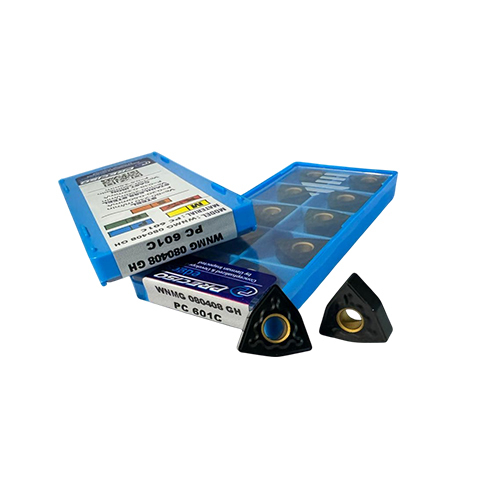

Turning insert

Turning insert Specification

- Material

- Carbide

- Usage

- Machinining

- Size

- 160408

- Product Type

- Turning Insert

- Color

- Black

Turning insert Trade Information

- Minimum Order Quantity

- 50 Pieces

- FOB Port

- INDIA

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 1 Days

- Sample Available

- No

- Packaging Details

- Standard Packing And As Per Client's Requirements

- Main Domestic Market

- [, ]

About Turning insert

Understanding Turning Inserts: A Comprehensive Guide

Turning inserts are crucial components in metalworking, particularly in lathe operations. They are small, precisely engineered pieces of carbide or ceramic material that are clamped into a tool holder to form the cutting edge.

Key Components and Their Functions:

-

Insert Shape:

- Triangular: Versatile for various turning operations, including facing, grooving, and threading.

- Rectangular: Ideal for general-purpose turning, especially for heavier cuts and longer tool life.

- Diamond: Optimized for finishing cuts, providing smooth surfaces and accurate dimensions.

- Round: Commonly used for internal turning operations like boring and facing.

-

Cutting Edge Geometry:

- Nose Radius: Determines the smoothness of the cut and the quality of the surface finish.

- Side Cutting Edge Angle: Influences chip formation and tool life, particularly in heavy-duty applications.

- End Cutting Edge Angle: Affects the cutting force and the ability to withstand high loads.

-

Chip Breaker:

- A groove or notch on the insert designed to control chip formation and prevent long, continuous chips that can damage the workpiece or the tool.

-

Insert Material:

- Carbide: Offers excellent wear resistance and toughness, making it suitable for a wide range of materials.

- Ceramic: Provides superior heat resistance and edge retention, ideal for high-speed, high-temperature applications.

Factors to Consider When Selecting Turning Inserts:

- Material to be Machined: The hardness, toughness, and machinability of the material will influence the choice of insert material and geometry.

- Machining Operation: The type of operation (turning, facing, grooving, etc.) will determine the appropriate insert shape and cutting edge configuration.

- Machining Parameters: Cutting speed, feed rate, and depth of cut will impact the selection of insert material and geometry.

- Desired Surface Finish: The required surface finish will influence the choice of nose radius and cutting edge preparation.

- Tool Life: The desired tool life will affect the selection of insert material and geometry, as well as the cutting parameters.

By carefully considering these factors, you can select the right turning inserts to optimize your machining processes and achieve the desired results.

FAQs of Turning insert:

Q: What is the recommended application for the Turning insert product?

A: The Turning insert is designed for industrial applications.Q: What is the shape of the Turning insert?

A: The Turning insert features a triangle shape.Q: What is the size of the Turning insert?

A: The size of the Turning insert is 160408.Q: What is the color of the Turning insert?

A: The Turning insert comes in black color.Q: What material is the Turning insert made of?

A: The Turning insert is made of carbide, making it suitable for machining applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Carbide Inserts Category

TURNING INSERT

Price 130.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : Industrial

Material : Carbide

Features : HSS

TURNING INSERT

Price 130.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : Industrial

Product Type : TURNING INSERT

Material : Carbide

Features : HSS

TURNING INSERT

Price 130.0 INR / Piece

Minimum Order Quantity : 100 Pieces

Usage : Industrial

Product Type : Turning insert

Material : [, ]

Features : HSS

PCD CBN Carbide Inserts

Price 800 INR / Piece

Minimum Order Quantity : 50 Pieces

Usage : CNC Machine

Product Type : Carbide Insert

Material : carbide

|

BK Enterprise

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |